Natural Plant Fiber vs. Recycled Polymers: Comparative Safety Analysis of Food Contact Materials

Food safety begins at the "entrance." With the increasing health awareness of consumers, food packaging, as the first line of defense for food safety, has attracted much attention for its safety. Choosing the right food contact material is crucial to the health of every consumer. Food packaging safety issues are becoming increasingly prominent, with risks such as excessive plasticizers, heavy metal contamination, and migration of harmful substances directly threatening consumer health.

Introduction: Food Safety Begins at the "Entrance"

Food is the paramount necessity of the people, and safety is the paramount concern in food. In recent years, food safety problems have emerged one after another, affecting the nerves of every consumer. According to the World Health Organization (WHO), approximately 600 million people worldwide fall ill each year from eating contaminated food, resulting in 420,000 deaths. Food packaging, as the "first line of defense" for food, is of paramount importance to safety. In addition to global data, China also faces food safety challenges. According to the sampling data of the State Administration for Market Regulation in 2023, a certain percentage of food packaging has quality problems every year, such as excessive migration and unqualified labels. Consumers' demand for safe and environmentally friendly food packaging is growing, driving the continuous innovation and development of food contact materials (FCMs).

Background: The "Past and Present" of Food Contact Materials

What are food contact materials (FCMs)? Simply put, they are all materials that come into direct contact with food, including packaging, containers, tableware, production equipment, and so on. Depending on the material, FCMs can be divided into several types, such as:

- Plastics: Including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polyvinyl chloride (PVC), etc.

- Paper: Including kraft paper, white cardboard, coated paper, etc.

- Metals: Including aluminum, iron, stainless steel, etc.

- Glass: Including soda-lime glass, borosilicate glass, etc.

- Natural Materials: Including bamboo fiber (with natural antibacterial properties), sugarcane bagasse (with good water absorption), straw, wood pulp, etc.

The development history of FCMs is also a history of continuous human exploration of food safety. From the initial natural materials (such as leaves and ceramics) to metals and glass after the Industrial Revolution, and then to the widely used plastics in modern society, the choice of food contact materials has undergone several changes. Each change is accompanied by technological progress and the pursuit of higher safety. For example, in the late 19th century, Pasteur's sterilization technology promoted the application of glass bottles in the field of food packaging; in the mid-20th century, the emergence of plastics completely changed the face of food packaging, but it also brought new environmental problems.

To regulate the use of food contact materials, governments have successively introduced relevant laws and standards, such as the European Union's (EC) No 1935/2004 regulation, which stipulates the general requirements for food contact materials, including not releasing substances that endanger human health, and not changing the composition and properties of food. The U.S. FDA food contact substance regulations, and China's GB 4806 series standards, such as GB 4806.1-2016 "National Food Safety Standard General Safety Requirements for Food Contact Materials and Products" and GB 9685-2016 "National Food Safety Standard Standard for the Use of Additives in Food Contact Materials and Products," clearly stipulate the migration limits and additive use of different materials. These regulations and standards make clear provisions on the production, use, and safety of FCMs to ensure the health and safety of consumers. For example, GB 9685-2016 specifies the migration limits of plasticizers (such as phthalates) in food contact plastics to prevent them from harming human health.

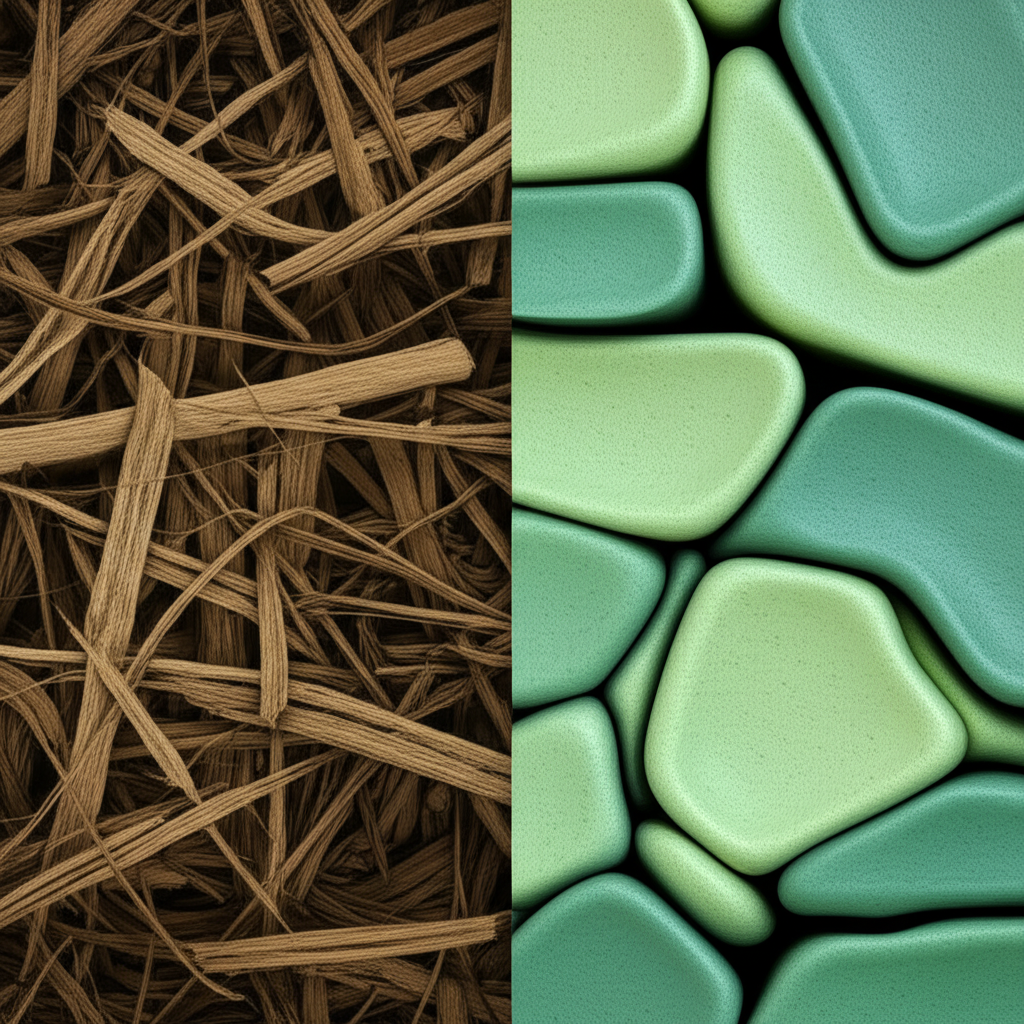

Natural Plant Fiber: A "Green" Choice to Return to Nature

What is Natural Plant Fiber?

Natural plant fiber refers to natural polymer materials extracted from plants. They are valuable resources gifted by nature, mainly derived from bamboo fiber (with natural antibacterial properties), sugarcane bagasse (with good water absorption), straw, wood pulp, etc. These materials are widely available and have the advantages of being renewable and biodegradable, making them ideal green and environmentally friendly food contact materials.

Advantages of Natural Plant Fiber

- Environmentally Friendly: The biggest advantage of natural plant fiber is its environmental friendliness. They are renewable resources, which can be continuously obtained, and can be biodegraded after use, reducing pollution to the environment.

- Abundant Resources: Compared to petroleum-based plastics, natural plant fibers have a wider range of sources and are relatively low in cost, especially in agriculturally developed areas.

- Safe and Non-toxic: Natural plant fiber itself is a natural material. Under the premise of complying with relevant standards, it can effectively reduce potential risks through appropriate treatment, and is relatively safe and non-toxic to the human body.

Applications of Natural Plant Fiber

Natural plant fiber has broad application prospects in the field of food packaging. For example:

- Tableware: Disposable tableware, food trays, etc., made of natural plant fiber, can replace traditional plastic tableware and reduce white pollution.

- Packaging Boxes: Fruit packaging, pastry packaging, etc., made of natural plant fiber, are not only environmentally friendly and beautiful, but also enhance the added value of products.

For example, [Brand Case: Liangpin Puzi] has already begun to use environmentally friendly paper boxes made of sugarcane bagasse in some of its pastry packaging. This packaging box is made of recyclable sugarcane bagasse pulp molding process, which can reduce carbon emissions by 70% compared to traditional plastic boxes. At the same time, the box design is simple and environmentally friendly, which better reflects the brand concept of Liangpin Puzi. [Brand Case: Starbucks] has launched coffee cups made of bamboo fiber in some stores. The cups are lightweight and durable, and have a certain heat insulation effect, which has been welcomed by consumers.

Potential Risks of Natural Plant Fiber

Although natural plant fiber has many advantages, there are also some potential risks that need to be addressed:

- Heavy Metal Residues: Plants may absorb heavy metals from the soil during growth. If not controlled properly, it may lead to excessive heavy metal residues.

- Microbial Contamination: If hygiene conditions are not strictly controlled during production and transportation, microbial contamination may be introduced, affecting food safety.

However, these risks are not uncontrollable. Through strict planting management, standardized production processes, and strict quality testing, these risks can be effectively reduced, ensuring the safety of natural plant fiber as a food contact material. For example, research from the [Data Support: Institute of Agricultural Environment and Sustainable Development, Chinese Academy of Agricultural Sciences] shows that by choosing soils with low heavy metal content for planting and using organic fertilizers, heavy metal residues in bamboo fiber can be significantly reduced. The study also pointed out that the use of high-temperature sterilization and ultraviolet disinfection and other measures can effectively control microbial contamination.

Recycled Polymers: A "Blue" Future of Recycling

What are Recycled Polymers?

Recycled polymers refer to polymer materials that are recycled and reused. According to different recycling methods, they can be divided into physical recycling and chemical recycling. Physical recycling is the process of directly reprocessing waste plastics into new plastic products after cleaning, crushing, and melting; chemical recycling is the process of depolymerizing waste plastics into monomers and then repolymerizing them to generate new polymer materials. They are an important way to solve plastic pollution problems, mainly from recycled plastic bottles, plastic films, and other waste plastic products. Through advanced recycling technology, these waste plastics can be transformed into new food contact materials, achieving the recycling of resources.

Advantages of Recycled Polymers

- Reduce Environmental Pollution: The use of recycled polymers can significantly reduce the generation of plastic waste and reduce pollution to the environment.

- Save Resources: Reduce dependence on primary resources, reduce energy consumption, and achieve sustainable development.

- Recycling: In line with the concept of circular economy, waste is transformed into valuable resources to achieve effective utilization of resources.

Applications of Recycled Polymers

Recycled polymers are also gradually being used in the field of food packaging. For example:

- Beverage Bottles: Beverage giants such as Coca-Cola and PepsiCo have begun to use recycled PET bottles in some of their products, actively responding to environmental protection calls.

- Food Boxes: Some fast food boxes and takeaway boxes have also begun to be made of recycled polymers, reducing dependence on primary plastics.

For example, [Brand Case: Danone] announced that by 2025, all of its packaging will be recyclable, reusable, or compostable, and will use a large amount of recycled plastic. Danone uses up to 50% recycled PET in its Evian mineral water bottles and is constantly increasing this percentage. [Brand Case: McDonald's] has launched tableware made of recycled PP in some parts of Europe. These plates are made of recycled fast food boxes and plastic cups, realizing the recycling of resources.

Potential Risks of Recycled Polymers

Similar to natural plant fiber, recycled polymers also have some potential risks that need to be addressed:

- Residue Migration: If cleaning is not thorough during the recycling process, it may lead to residues migrating into food, affecting food safety.

- Additive Migration: Some plastic products may contain harmful additives. If not handled properly during the recycling process, additives may migrate, posing a threat to human health.

To reduce these risks, advanced recycling technology and strict quality control systems are needed. For example, [Technical Support: GRS Certification] The Global Recycled Standard (GRS) certification is an international voluntary product standard that specifies the requirements for recycled material content, supply chain traceability, social responsibility, and environmental practices. Through GRS certification, companies can prove that their products use recycled materials that meet the requirements and ensure that the production process of the products meets environmental protection and social responsibility standards. Companies that obtain GRS certification need to establish a complete traceability system to ensure the traceability of recycled materials; at the same time, they also need to conduct regular audits and tests to ensure the quality and safety of products.

Safety Comparison: A Contest Between "Green" and "Blue"

Raw Material Safety

- Natural Plant Fiber: Its safety is greatly affected by the plant's growing environment, such as soil and water sources. The use of pesticides and fertilizers may also lead to residues. Therefore, it is crucial to choose plant fibers with good growing environments and strict pesticide control.

- Recycled Polymers: The source of recycling is complex and may contain a variety of pollutants, such as oil and chemical residues. Therefore, efficient cleaning and separation technology is the key to ensuring its safety.

A report by the [Data Comparison: German Federal Institute for Risk Assessment (BfR)] showed that under strict control, the heavy metal content of natural plant fiber and recycled polymers is lower than EU standards, but recycled polymers that have not been properly cleaned may have a higher risk of pollutant residues.

Processing Safety

- Natural Plant Fiber: The processing process may involve bleaching, preservation, and other treatments. If these treatments are not properly controlled, harmful substances may be introduced.

- Recycled Polymers: It needs to be cleaned, disinfected, reshaped, and other treatments, and each link may introduce new risks.

[Technical Case: Solvent-Free Bleaching Technology] Solvent-free bleaching technology is a bleaching method that uses environmentally friendly oxidants such as ozone and hydrogen peroxide to replace traditional chlorine-based bleaching agents. This technology can effectively remove pigments and impurities from plant fibers and does not produce harmful chlorinated organic matter, making it more environmentally friendly and safe.

Migration Testing and Evaluation

Migration testing is an important means of evaluating the safety of food contact materials. By simulating the contact between food and packaging materials, it is detected whether harmful substances will migrate into the food. Common migration testing items include heavy metal migration, plasticizer migration, and monomer migration. Countries have formulated corresponding migration testing standards and methods to ensure the safety of food contact materials. For example, the European Union's (EC) No 10/2011 regulation details the migration testing methods and limit requirements for plastics for food contact.

Conclusion and Outlook: Safe Packaging, Protecting Health

Food contact material safety is an important part of food safety and is directly related to the health of consumers. Natural plant fiber and recycled polymers, as two environmentally friendly food contact materials with development potential, have their own advantages and disadvantages.

- Natural Plant Fiber: It is more suitable for disposable tableware, fruit packaging, and other food packaging that does not require high strength and has a short contact time.

- Recycled Polymers: It is more suitable for beverage bottles, food boxes, and other food packaging that requires high strength and barrier properties and needs to be used for a long time.

In the future, with the progress of science and technology and the continuous improvement of consumers' health needs, the development of food contact materials will show the following trends:

- Stricter Supervision: Governments will further strengthen the supervision of food contact materials, raise the threshold for access, and increase the intensity of spot checks.

- More Advanced Technology: The research and development of bio-based materials will pay more attention to performance improvement and cost control; the application of degradable materials will be more extensive, but it is still necessary to solve the problems of degradation conditions and the safety of degradation products.

- More Environmentally Friendly Materials: Encourage the use of more environmentally friendly materials, such as bio-based plastics and degradable plastics, and promote the research and development and application of related technologies.

Let us work together to choose safer and more environmentally friendly food packaging, provide consumers with healthier food, and protect our common earth!