Introduction: In today's competitive market, high-end packaging design increasingly emphasizes conveying quality and brand value through details. In addition to basic printing, skillful use of special post-printing processes can greatly enhance the visual impact and tactile experience of packaging, making it stand out from the crowd. Hot stamping, UV coating, and embossing (debossing) are three of the most commonly used and effective post-printing processes, widely applied in various high-end packaging. PackRapid, with its rich technological experience and advanced equipment, can bring out the best in these processes. This article will detail the characteristics and effects of these three processes, and provide professional design suggestions.

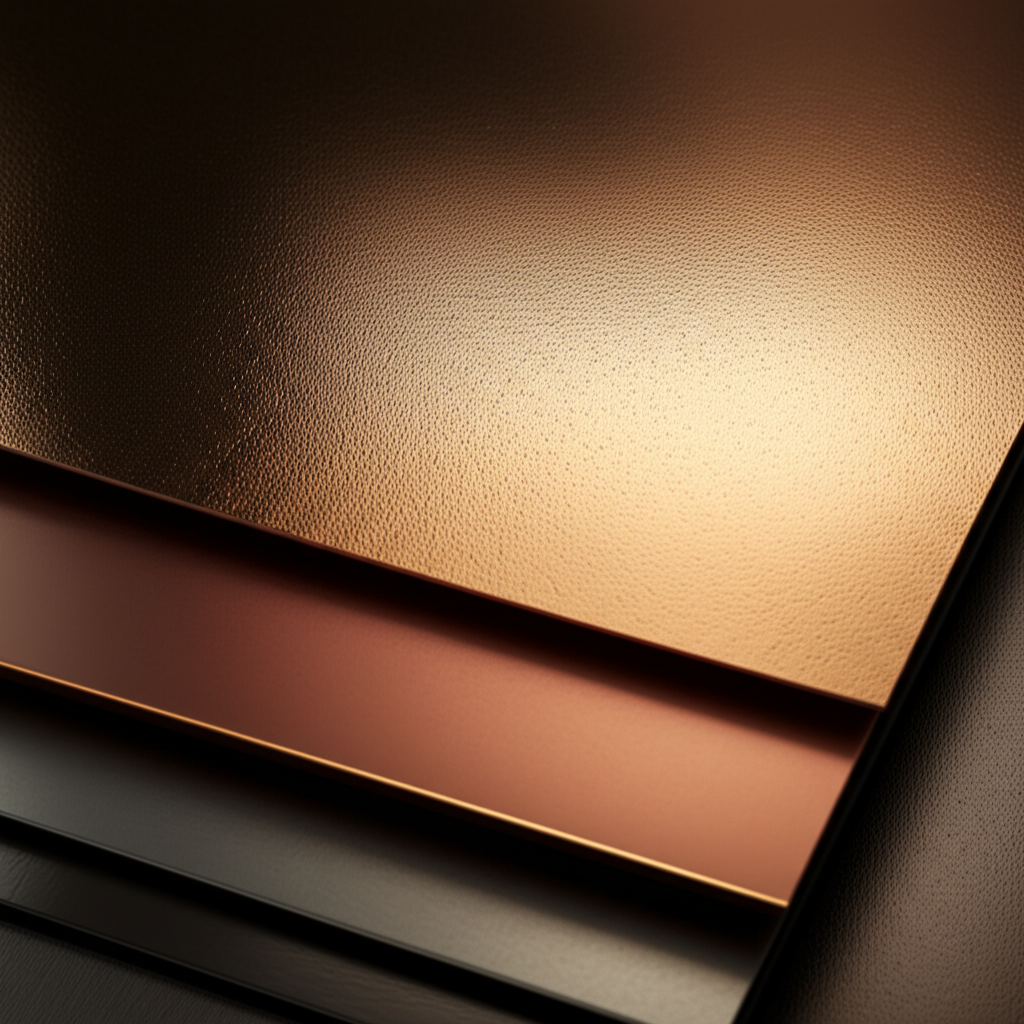

1. Hot Stamping: Illuminating Luxurious Radiance

- Process Principle: Using the principle of heat-transfer, metal foil (or other colored electro-aluminum foil) is heated and pressed onto the surface of paper or other substrates, forming graphics and text with a strong metallic luster or special color.

- Effect Characteristics:

- Visual Prominence: Strong metallic luster, vibrant colors, instantly catching the eye and creating a luxurious, noble, and refined visual effect.

- Enhanced Texture: The hot-stamped portion is usually slightly raised or flat, creating a contrast with the paper and adding tactile layers.

- Diverse Colors: In addition to the common gold and silver, there are many other colors of metal foil available, including red, blue, green, black, and laser, and even special effects such as matte and brushed finishes.

- PackRapid Design Suggestions:

- Moderate Use: Hot stamping should not be overused; it is typically used for brand logos, key text, decorative lines, or small patterns to add emphasis.

- Line Thickness: Too thin lines or text may be unclear or broken when hot stamped. A minimum line thickness of 0.2mm is recommended.

- Material Matching: Hot stamping looks better on dark, matte, or textured papers, creating a strong contrast. PackRapid offers a variety of special papers suitable for hot stamping.

- Coordination with Printing: Hot stamping patterns usually require separate film output and hot stamping plate production. When designing, consider the registration accuracy of hot stamping and printing.

2. UV Coating: Shaping a Crystal-Clear Focus

- Process Principle: A layer of UV (ultraviolet light-curing) varnish is applied to a specific area or the entire surface of a printed product. After being irradiated by ultraviolet light, it quickly cures, forming a high-gloss, wear-resistant transparent bright film.

- Effect Characteristics:

- Local Highlighting: The most common application is spot UV, making specific areas of graphics and text (such as logos, product patterns, and text) appear with a crystal-clear gloss, creating a strong contrast with the surrounding matte or ordinary printing.

- Rich Texture: The UV layer has a certain thickness and smoothness, significantly enhancing the packaging's tactile and visual layers.

- Special Effects: In addition to high-gloss UV, there are matte UV, frosted UV, imitation metal etching UV, and foamed UV (creating a raised effect), among other special effects UV, providing more design possibilities.

- Protective Properties: The UV layer increases the wear resistance, scratch resistance, and moisture resistance of printed products.

- PackRapid Design Suggestions:

- Highlighting Key Elements: Spot UV is ideal for emphasizing brand elements or key product highlights.

- Contrast with Base Color: High-gloss UV on a dark or matte base color yields the best effect.

- Avoid Very Small Areas: Too small or complex UV areas may be difficult to control precisely, resulting in poor results.

- Consider Paper Absorbency: Different papers absorb UV varnish differently, which may affect the final glossiness. PackRapid will adjust process parameters according to paper characteristics.

3. Embossing/Debossing: Sculpting Three-Dimensional Tactile Sensation

- Process Principle: Using a pair of positive and negative metal dies, pressure is applied to emboss (raised) or deboss (indented) graphics and text on the paper surface.

- Effect Characteristics:

- Three-Dimensional Tactile Sensation: The most significant characteristic is that it gives the packaging a strong tactile feel, conveying quality and refinement through the touch.

- Light and Shadow Effects: Embossed or debossed graphics and text create subtle light and shadow changes under light, adding to the visual richness.

- Subtle Luxury: Even without printing or hot stamping (referred to as "blind embossing" or "blind debossing"), simple embossing or debossing can create a subtle yet high-end texture.

- Multi-Level Embossing: Multiple layers and depths of embossing can be achieved, making patterns more three-dimensional and artistic.

- PackRapid Design Suggestions:

- Pattern Selection: Suitable for patterns, logos, or thicker text with a distinct outline and area. Too fine details may be difficult to clearly show.

- Paper Weight: It is recommended to use paper with higher grammage and better toughness (such as 250gsm or higher cardstock or specialty paper) to achieve a more pronounced and durable embossing effect and prevent paper breakage. PackRapid has extensive experience in handling thick paper.

- Combination with Printing/Hot Stamping: Printing/hot stamping is followed by embossing/debossing registration (referred to as "registered embossing") to create a more impactful effect.

- Reverse-Side Effect: Embossing creates a corresponding indentation on the back of the paper; the design should consider the visual effect of the back or use double-sided mounting to avoid this.

4. Combination of the Three Processes

Skillfully combining hot stamping, UV coating, and embossing can often create a stunning effect where 1+1+1 > 3. For example:

- Hot Stamping + Embossing: Makes the hot-stamped pattern more three-dimensional and creates a relief effect.

- Spot UV + Debossing: Applying UV to the indented area creates a unique visual and tactile effect.

- Printing + Spot UV + Embossing: Combining multiple processes creates an ultra-rich sensory experience.

PackRapid's Professional Assurance: We have advanced automated hot stamping machines, UV coating equipment, and high-precision embossing equipment, as well as an experienced team of technicians. From design file review and plate making to actual production, PackRapid strictly controls every step to ensure that the final process effect perfectly meets your expectations, creating truly impressive high-end packaging for your brand.

Conclusion: Hot stamping, UV coating, and embossing are powerful tools to enhance packaging design texture and convey brand value. Understanding and cleverly using these processes can give your packaging a visual and tactile edge. PackRapid is dedicated to perfectly combining sophisticated post-printing processes with your creative designs. If you want to add unique charm to your packaging through these processes, welcome to communicate in-depth with our design and process experts; we will be happy to provide you with professional advice and high-quality implementation solutions.